LEAN 4.0

Lean in the digital era

Lean Consulting

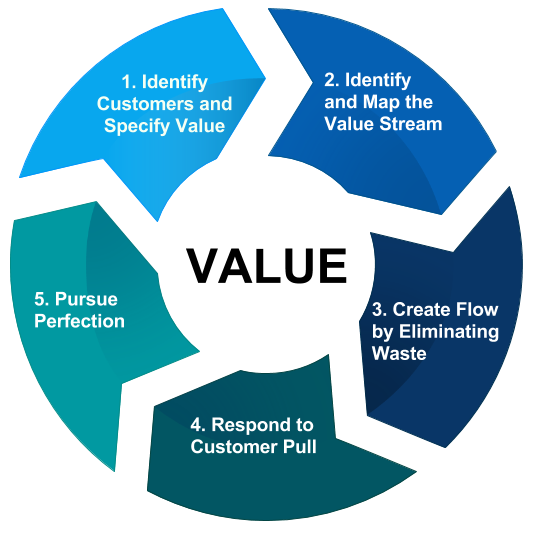

Lean is a culture. Adopting Lean Principles as the main method brings your operations to a world class level. Lean is not only concepts and tools, it’s a way of life. At Agilean we think by coaching your team, we can help you put in place a Lean Culture that in the long run, will bring good for your clients, employees and partners.

Lean has to be applied in every aspect of the business. By implementing Lean and working together we can identify and execute key opportunities for improving your business and quickly see positive results. Lean can be applied in all industries. From manufacturing, services and even Research & Development.

We work with facts (data)

The more we get, the hapier we are !

Manufacturing

system diagnostic

Consulting

Manufacturing

system diagnostic

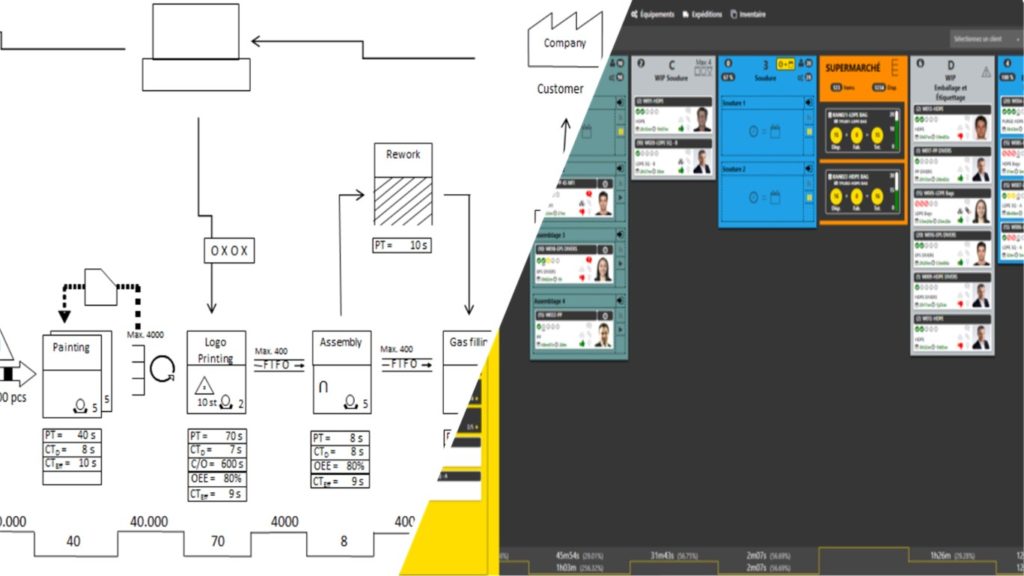

Comprehensive review of the manufacturing system using value stream mapping (VSM).

Definition of the current state and sources of waste in your processes and in your operations.

Recommendations and potential gains of a Lean manufacturing strategy (Hoshin Kanri).

Complete plan for digital initiatives and solutions to support your efficiency objetcives.

With ALIX, your Value Stream is LIVE. No need to map the Value Streams.

Sources of waste can be identified in real-time directly in the production board.

We can rely on ALIX’s data to back our recommendations and potential gains of a Lean manufacturing strategy (Hoshin Kanri).

Complete plan for digital initiatives and solutions to support your efficiency objectives.

Optimization projects

Consulting

Optimization projects

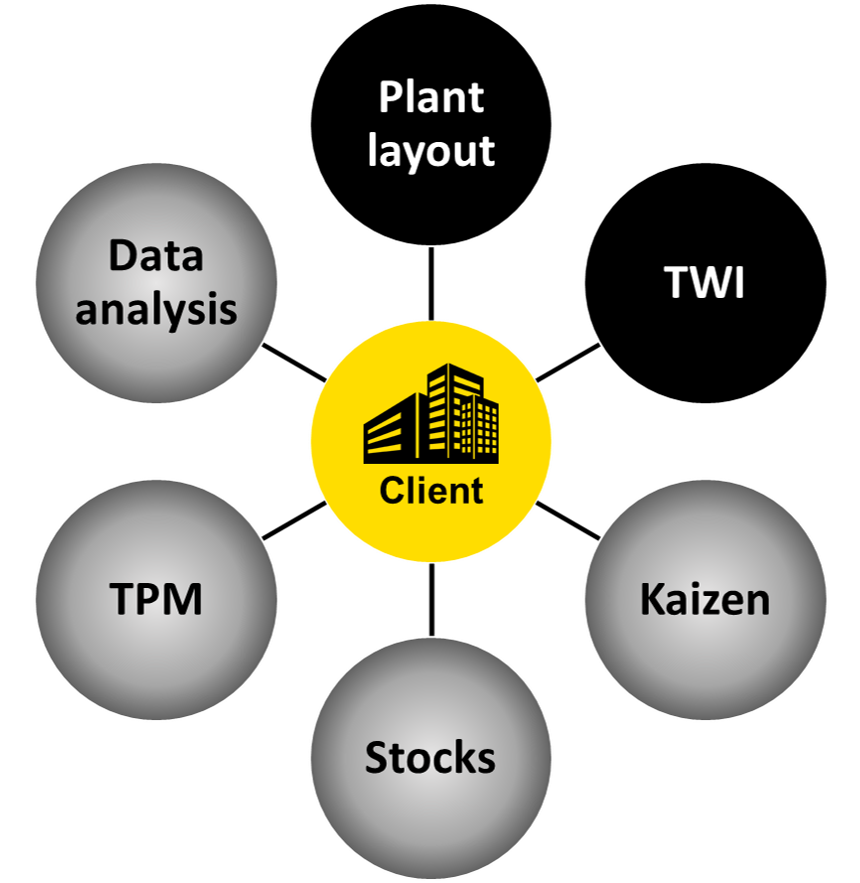

Partial or complete plant layout (material and information flow)

TWI (Training Within the Industry) – Work Instruction and standard work

Kaizen workshop (3P, Quality, 5S, SMED, cell layout, etc…)

Stock management (raw material & finish goods, Kanban & PFEP)

TPM methodology and maintenance management

Data analysis projects (six sigma / big data)

In our Kaizen workshop, participant need information in order to get best solution. With ALIX, you will have access to tons of data to use and answer your toughest questions.

When trying to optimize your stocks, tools embedded in ALIX like PFEP and Kanban will give you complete history of your stocks and ease your stock optimization project.

To implement TPM methodology, you better know the utilization of your equipment.

With ALIX’s equipment monitoring and hour tracking based on work from your operations (production board) or by connecting your equipment through IIoT, we can provide real-time OEE and enough data to come up with the best TPM implementation.

With all data collected in real-time in your operations, we can do the right data analysis projects and analytics to better understand and/or dig into recurring problems that need to be solved.

Continuous Improvement Culture

Coaching

Continuous Improvement Culture

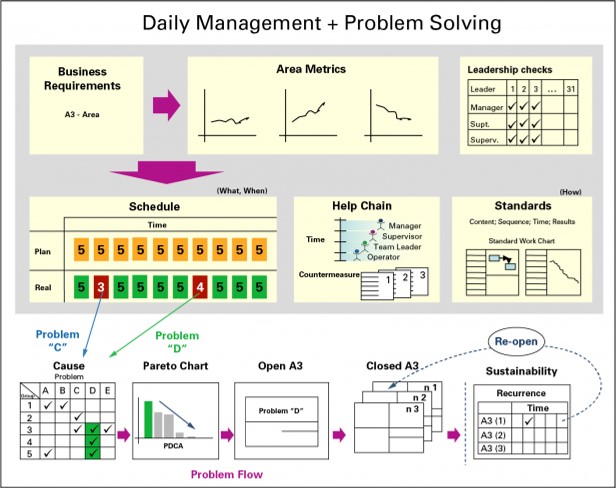

Daily Management System (DMS) :

Daily routine for supervisors and their teams

Problem solving skills and culture (A3)

Improvement management system (PDCA)

Business process mapping and improvement

(production & services)

Deployment of an Operational Excellence strategy

With dashboards to give you a complete insight on your operations, following-up in real-time would never be that easy.

ALIX let you shape information the way you want in order to take the right decisions as soon as possible. Thanks to all data, the only limit will be your imagination in creating the right dashboards.

Your team works with us and learns

If we have to spend time in a room, kaizen team will be working. Production employees need to be active to be at their best.

If theory needs to be transfered to team members, it will always be brief and supported by easy to understand documentation.

We rely on facts to understand. As we dig with the team on available data, they will learn that field observations are essentials to make sure we fully understand and take best corrective measures (action plan).

Team members will often require help from other employees and managers to collect all the information. Even people outside of the workshop will be involved.

Every time we hold a kaizen event, there is a communication plan for both the team members and employees of the company.